Redefining the construction industry with innovative solutions, cuttin-edge technology and sustainable practices

Profile Bending 2025-11-19

Bending processing is a fundamental technique in modern manufacturing, applied across industries ranging from automotive and aerospace to construction, energy, and industrial machinery. It enables the transformation of raw materials—tubes, profiles, and sheets—into precise, functional, and aesthetically refined components. In recent years, technical upgrades in bending processing have significantly enhanced precision, efficiency, and versatility, allowing manufacturers to meet increasingly complex demands. This article explores these upgrades in depth, focusing on innovations, material adaptations, automation, and industrial implications.

1. The Evolution of Bending Processing

Historically, bending processing relied heavily on manual methods, simple mechanical presses, and basic tooling. While these approaches could handle simple shapes, they were limited in terms of repeatability, precision, and adaptability to modern high-performance materials. With the rise of digital manufacturing, new bending technologies have emerged that address these limitations:

Numerical Control (NC) and Computer Numerical Control (CNC) Machines: Digital systems now allow precise control of bending angles, radii, and sequences, minimizing human error and reducing material waste.

Advanced Tooling Materials: High-strength, wear-resistant dies and punches extend service life and maintain dimensional accuracy for high-volume production.

Simulation Software: Bending simulations predict spring-back, deformation, and potential cracks, enabling optimized tooling and process parameters before actual production.

These innovations provide a foundation for modern upgrades and enable the processing of a broader range of materials.

2. Multi-Material Adaptability: Tubes, Profiles, and Sheets

Technical upgrades in bending processing increasingly focus on multi-material adaptability, as industries require versatility in handling diverse materials:

#A. Tubes

Tube bending is widely used in automotive exhaust systems, hydraulic lines, and structural frameworks. Modern upgrades include:

Mandrel and Rotary Draw Bending: These techniques reduce deformation, wrinkling, and ovality, especially for thin-walled tubes.

Adaptive Force Control: Sensors monitor bending forces in real time, adjusting pressure to account for tube diameter variations or wall thickness inconsistencies.

Alloy Compatibility: Enhanced tooling accommodates aluminum, stainless steel, and high-strength steel tubes without compromising shape accuracy.

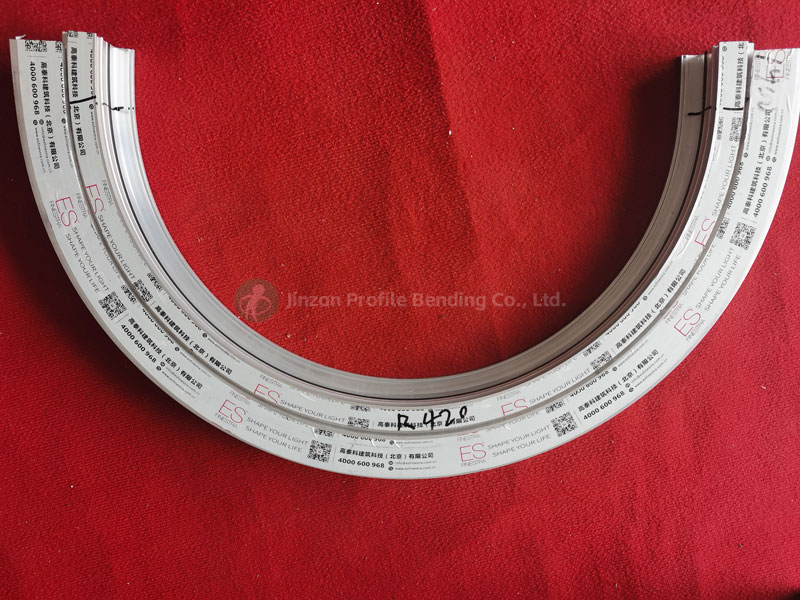

#B. Profiles

Profiles—such as extruded aluminum or steel channels—are increasingly used in structural and decorative applications. Upgrades for profile bending include:

Profile-Specific Dies: Custom-designed dies prevent twisting or distortion of complex cross-sections during bending.

Segmented Tooling: Multi-segment dies allow gradual bending, reducing internal stress concentrations.

Precision Length and Angle Control: CNC systems monitor and correct profile length during bending to maintain tight tolerances.

#C. Sheet Materials

Sheet metal bending remains essential for automotive panels, enclosures, and industrial housings. Innovations include:

Press Brake Automation: Servo-electric and hydraulic press brakes with CNC control achieve consistent angles across long sheets.

Laser-Assist Bending: Localized heating reduces spring-back in high-strength or thick sheets, improving accuracy.

Sheet Protection Technology: Soft tooling or polymer coatings prevent surface scratches while maintaining bending quality.

These upgrades enable manufacturers to process a wide range of geometries and thicknesses without compromising structural integrity.

3. Automation and Intelligent Control

Automation is a critical driver of efficiency and consistency in bending processing. Modern systems integrate sensors, software, and robotics to optimize every step:

Real-Time Monitoring: Load cells and displacement sensors track bending forces and material behavior during processing. Deviations trigger automatic corrections to maintain accuracy.

Robotic Material Handling: Automated loading, positioning, and unloading reduce manual labor, enhance safety, and support continuous production.

Integrated Quality Feedback: Measurement systems capture post-bend dimensions and feed data back to CNC controllers, enabling adaptive corrections for subsequent bends.

Digital Twin Technology: Simulated models replicate real-world bending conditions, allowing predictive maintenance, process optimization, and virtual prototyping.

Automation reduces waste, increases throughput, and ensures high reproducibility, which is critical for industries with tight tolerances.

4. Precision and Process Optimization

Technical upgrades also focus on precision and process efficiency. Manufacturers now employ advanced methods to minimize deformation, reduce residual stress, and improve final product quality:

Spring-Back Compensation: Modern software calculates the expected spring-back of each material type, adjusting bending angles to achieve exact specifications.

Incremental Bending Techniques: Multi-pass bending distributes stress gradually, minimizing cracks and distortion.

Hybrid Bending Methods: Combining mechanical and thermal bending improves flexibility and allows processing of high-strength materials that were previously difficult to bend.

High-Speed Production: Advanced machines maintain high accuracy even at increased bending speeds, enhancing productivity without sacrificing quality.

These techniques collectively reduce rework, scrap rates, and operational costs while improving end-product reliability.

5. Industrial Applications and Benefits

The upgraded bending processes are applied across multiple industries:

Automotive: Exhaust systems, chassis components, and roll cages benefit from high-precision tube bending with tight tolerances.

Aerospace: Lightweight aluminum profiles and high-strength steel sheets require precise bends for structural integrity.

Construction: Steel profiles and metal panels for buildings and bridges demand accuracy, repeatability, and minimal deformation.

Energy and Utilities: Tubes and sheet components for pipelines, solar mounts, and wind energy frameworks require consistent quality under high-stress conditions.

Industrial Equipment: Hydraulic systems, enclosures, and machinery frames rely on tube, profile, and sheet bending for both functionality and aesthetics.

Upgraded bending processing ensures these industries achieve both performance and cost-effectiveness.

6. Future Trends in Bending Technology

Looking ahead, technical upgrades in bending processing are expected to focus on:

Artificial Intelligence (AI) Integration: AI-driven predictive adjustments and adaptive control for dynamic production conditions.

Smart Factory Compatibility: Bending machines connected to IoT networks for real-time monitoring, remote diagnostics, and production scheduling.

Material Innovation Adaptation: New lightweight alloys, composites, and high-strength steels will drive further upgrades in tooling and process control.

Eco-Friendly Processing: Energy-efficient servo motors, reduced waste strategies, and environmentally friendly lubricants align bending technology with sustainability goals.

These trends point toward increasingly intelligent, flexible, and sustainable bending solutions.

Technical upgrades in bending processing have transformed how manufacturers handle tubes, profiles, and sheet materials. With innovations in multi-material adaptability, automation, precision control, and intelligent monitoring, modern bending processing now delivers unprecedented accuracy, efficiency, and versatility. These advancements not only meet the demands of complex industrial applications but also support the shift toward smart manufacturing and sustainable production practices. As industries continue to evolve, the ongoing refinement of bending technologies will remain a cornerstone of high-performance, high-precision manufacturing worldwide.