Redefining the construction industry with innovative solutions, cuttin-edge technology and sustainable practices

Profile Bending 2025-08-12

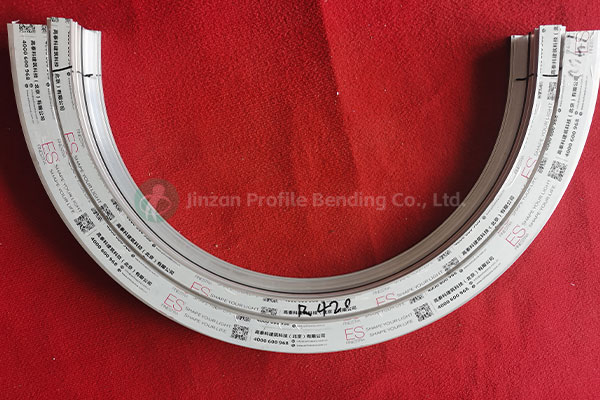

Steel curving is an essential process in various engineering and construction applications, allowing for the creation of aesthetically pleasing and structurally sound components. As industries evolve, the future of steel curving is shaped by emerging trends, innovative techniques, and a growing emphasis on sustainability.

Trends in Steel Curving

1.Increased Demand for Customization

The demand for customized solutions in construction and manufacturing is on the rise. Clients are seeking unique designs that reflect their brand identity and meet specific functional requirements. This trend is driving steel curving companies to adopt more flexible manufacturing processes. Advanced CNC (Computer Numerical Control) machines and software enable precise curving of steel elements, allowing for intricate designs that were previously challenging to achieve.

2.Integration of Digital Technologies

The integration of digital technologies, such as Building Information Modeling (BIM), is revolutionizing the steel curving industry. BIM not only facilitates better design and visualization but also allows for seamless collaboration among architects, engineers, and contractors. By using BIM, stakeholders can simulate the curving process, identify potential issues, and optimize designs before physical fabrication begins. This reduces waste and enhances efficiency.

3.Emphasis on Aesthetic Appeal

As architectural designs become more adventurous, the use of curved steel elements is increasingly common in modern buildings. Architects are embracing steel curving to create dramatic facades, roofs, and structural supports. The aesthetic appeal of curved steel contributes to the overall visual impact of a structure, making it a preferred choice for iconic buildings and public spaces.

Innovations in Steel Curving

1.Advanced Fabrication Techniques

Innovations in fabrication techniques are transforming the way steel is curved. Traditional methods such as bending and rolling are being supplemented by advanced technologies like laser cutting and water jet cutting. These techniques allow for greater precision and the ability to create complex geometries with minimal material waste. Such innovations enhance the overall quality of curved steel components.

2.Robotic Automation

The incorporation of robotics in the steel curving process is gaining traction. Robotic arms equipped with advanced sensors can perform intricate curving tasks with high precision and speed. Automation not only improves productivity but also enhances worker safety by reducing the need for manual handling of heavy steel components. This shift towards automation is setting new standards for efficiency in the industry.

3.3D Printing of Steel Components

The advent of 3D printing technology is beginning to influence the steel curving landscape. While still in its early stages, 3D printing allows for the creation of customized steel components with complex shapes that are difficult to achieve through traditional methods. This technology offers the potential for on-demand production, reducing lead times and inventory costs.

Sustainability in Steel Curving

1.Recycling and Material Efficiency

Sustainability is a significant focus in the steel industry, and steel curving is no exception. Steel is one of the most recycled materials globally, and this characteristic is being leveraged to minimize environmental impact. By using recycled steel in curving processes, companies can reduce their carbon footprint while maintaining the integrity and strength of the material.

2.Energy-Efficient Processes

As industries strive to reduce energy consumption, steel curving processes are also evolving. Manufacturers are investing in energy-efficient machinery and practices that lower energy usage during fabrication. Additionally, the use of renewable energy sources, such as solar or wind power, is becoming more common in steel production facilities.

3.Sustainable Design Practices

Architects and engineers are increasingly incorporating sustainability into their designs. This includes using curved steel elements that not only enhance aesthetics but also contribute to energy efficiency and environmental performance. For example, curved steel can be utilized in structures that optimize natural light and airflow, leading to reduced energy consumption in heating, cooling, and lighting.

The future of steel curving is bright, characterized by significant trends, innovations, and a strong commitment to sustainability. As the demand for customized, aesthetically appealing, and environmentally friendly solutions continues to grow, the steel curving industry is poised to adapt and thrive. By embracing advanced technologies and sustainable practices, companies can not only meet the challenges of the modern market but also contribute positively to the environment and society. As we look ahead, the evolution of steel curving will undoubtedly play a crucial role in shaping the built environment of the future.