Redefining the construction industry with innovative solutions, cuttin-edge technology and sustainable practices

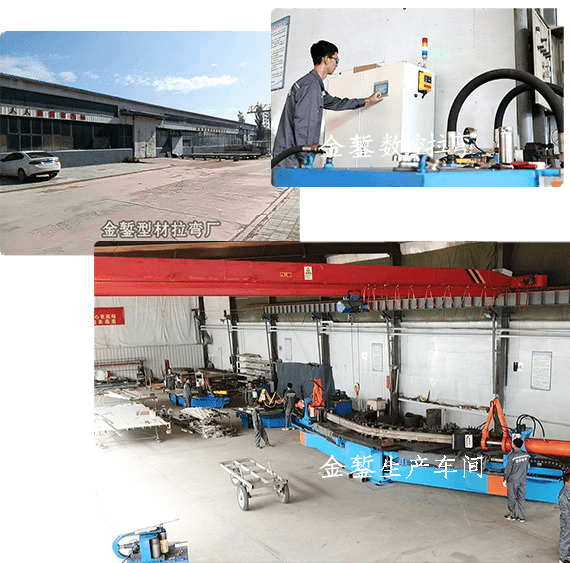

With advanced equipment, experienced engineers, and a long-term reserve of draw bending technicians, our company periodically sends teams abroad to exchange and learn foreign technologies, which are then introduced into our domestic factories. This ensures that we continuously advance in both technology and equipment through sustained communication and innovation!

Guided by a commitment to customer responsibility and a focus on minimizing draw bending tolerances, Jinzan Draw Bending ensures that every customer order is translated into practical project implementation. We strictly follow line drawings for step-by-step manufacturing and processing, systematically reducing errors!

Jinzan Draw Bending Processing serves customers nationwide. We allocate more budget annually to technology and equipment to improve the hardware and software facilities for draw bending, as well as personnel allocation!

Door and window profile bending is no longer just a specialized fabrication process—it is a key enabler of modern architectural performance and aesthetics.

Plastic steel bending solutions provide a reliable and versatile approach to creating customized architectural profiles and curved structural designs.

The quality of the arc bending forming process is not determined by a single factor but by the coordinated interaction of materials, tooling, equipment, process parameters, and quality control practic